Installing Servo's Correctly

Installing Servo's Correctly |

|

|

|

|

|

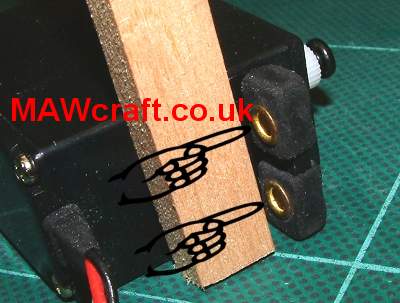

I've checked over a few beginner's models and I have noticed in nearly

all cases that the brass inserts have been installed in the rubber anti-vibration

mounts the wrong way. After investigation I know that both JR and Futaba

(or kit manufacturers) do not mention any where in their user manuals about

the correct way to install a servo.

|

| Tip Drill and insert the screws, then remove the screws, put a drop of thin cyno down the holes and allow to set before reassembling. This makes for a much stronger fixing. |

|

|

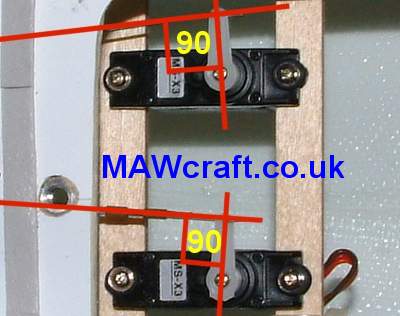

When installing the rudder, elevator and aileron servo's complete the

following procedure and you won't go wrong

|

| Tip Remove the other 3 arms of the servo head, (see pictures) this reduces the chances of the servo's getting tangled up with loose wiring and possibly disconnecting a plug and socket in flight with the obvious disastrous consequences. |

|

Close Window |

|